Main machinery:

Supporting machinery:

- Conveyor

- Grab bucket (to feed the raw material to the processing line)

- Crumb Filling Station

- Bucket Elevator

- Scrubber

- Metal detector

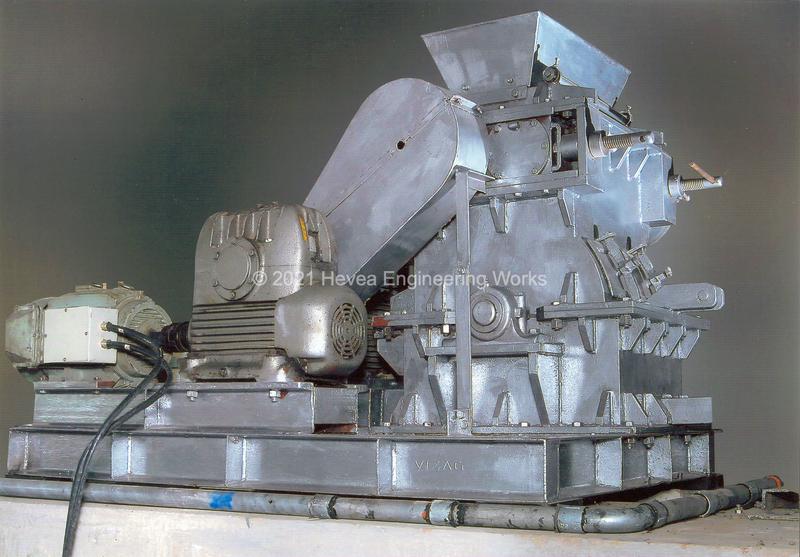

Slab Cutter

This is the first machine in the process line. This machine is used for initial break up of cup lump and rubber blocks.

Capacity: Various models available with capacity ranging from 1 T/Hr to 3 T/Hr.

| Base Frame | Fabricated with ISMB 250 or equivalent. |

|---|---|

| Chamber | Fabricated with MS Plates. |

| Fixed Cutter | Mild Steel casting. |

| Hinged Cutter | Fabricated from MS Plates with hard faced cutting edge. |

| Rotating Cutter | Mild Steel Casting with hard faced cutting edge. |

| Bearing | Spherical Roller Bearings with Adapter Sleeve. |

| Gear Box | Worm/Helical Reduction Gear Box. |

| Motor | Squirrel cage Induction Motor. |

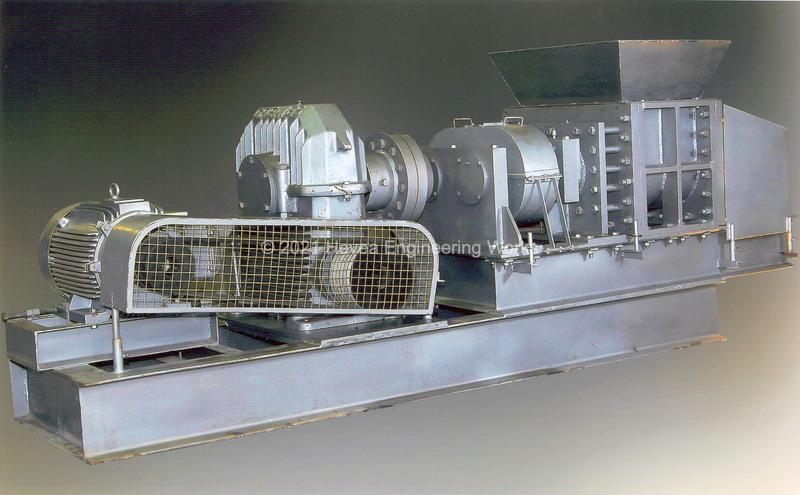

Pre-Breaker

This machine is used for size reduction in the initial stage.

Capacity: Various models available with capacity ranging from 1 T/Hr to 3 T/Hr.

| Base Frame | Fabricated with ISMB 300 and ISMB 250 or equivalent. |

|---|---|

| Chamber | Fabricated with MS Plates. |

| Bearing Housing | Fabricated with MS Plates. |

| Scroll | Mild Steel Casting with hard faced cutting edge. |

| Gear | EN 24. |

| Bearings | Spherical roller and Thrust Bearings. |

| Gear Box | Worm/Helical reduction gear box. |

| Motor | Squirrel cage Induction Motor. |

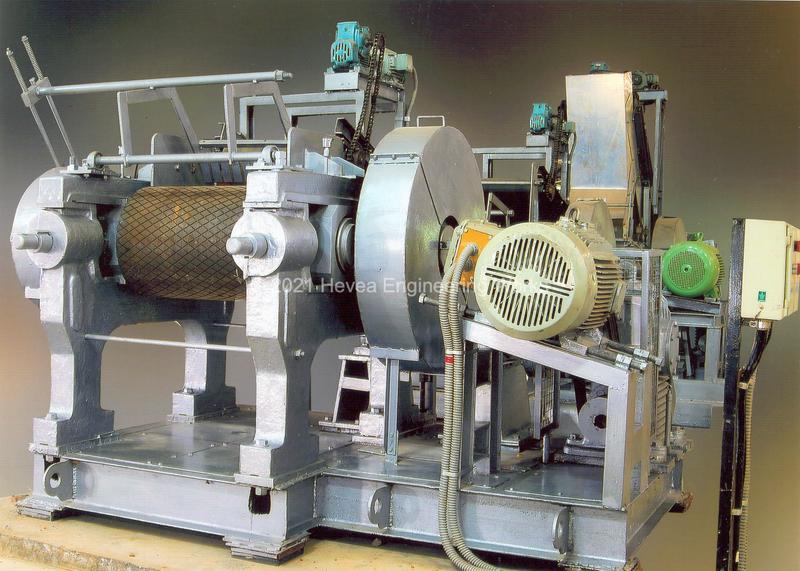

Creper

This machine is used to cut and shear the rubber after pre cleaning.

Capacity: Various models available with capacity ranging from 0.5 T/Hr to 2 T/Hr.

| Base Frame | Fabricated with ISMB 200 or equivalent. |

|---|---|

| Stand and Block | Grey Cast Iron. |

| Bearing | Phosphor Bronze Bush or Spherical roller bearing. |

| Roller | Graded Cast Iron. |

| Gear Box | Worm/Helical/Shaft mounted reduction gear box. |

| Motor | Squirrel cage Induction Motor. |

Hammer Mill

Hammer mill is used to cut and clean the rubber in the intermediate stage/final stage.

Capacity: Various models available with capacity ranging from 1 T/Hr to 2 T/Hr.

| Base Frame | Fabricated with ISMB 200 or equivalent. |

|---|---|

| Chamber | Fabricated with MS Plate. |

| Screen | MS Plate. |

| Hammers | OHNS. |

| Rotor Disc | MS Plate. |

| Bearings | Spherical roller bearing with adaptor sleeve. |

| Hoper | Fabricated with MS Plate. |

| Motor | Squirrel cage Induction Motor. |

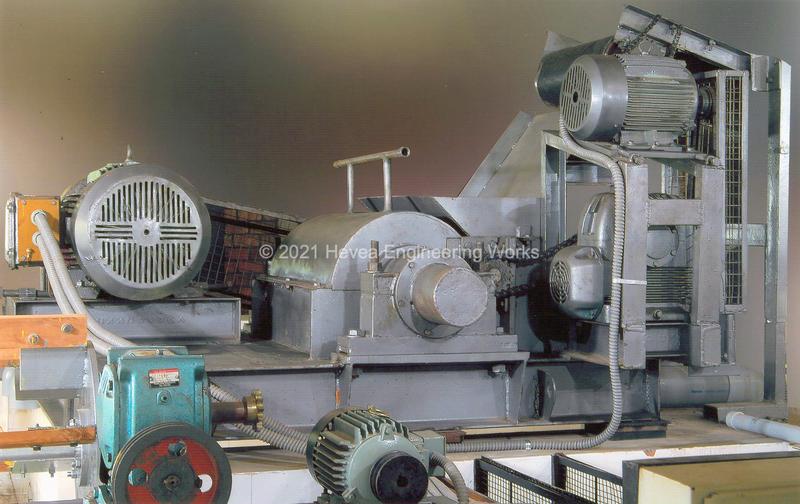

Shredder

This machine is used for size reduction in intermediate/final stage.

Capacity: Various models available with capacity ranging from 1 T/Hr to 3 T/Hr.

| Base Frame | Fabricated with ISMB 200 and MS Plate. |

|---|---|

| Main Roller | Graded cast iron. |

| Feed Roller | Stainless steel 304 grade. |

| Cutting Blade | Grey Cast Iron. |

| Bearings | Spherical Roller bearing with adaptor sleeve. |

| Gear Box | Worm/Helical reduction gear box. |

| Motor | Squirrel cage Induction Motor. |

Dryer

For drying the final rubber granules.

Capacity: Various models available with capacity ranging from 0.5 T/Hr to 3 T/Hr.

| Tunnel | Fabricated with channels, angles and Aluminium/Stainless sheets with 100 MM thick insulation. |

|---|---|

| Drier boxes | Fabricated with Stainless Steel sheets and MS fabricated trolley. |

| Hot Air Blower | Fabricated with MS /SS sheets. |

| Exhaust Blower | Fabricated with Stainless sheet. |

| Motor | Squirrel cage Induction Motor. |

Hydraulic Press

The dried rubber is pressed into blocks in this machine.

Capacity: 100 T, with output of 40 to 50 Bale/Hr. (Single chamber)

| Chamber | Mild Steel casting/fabricated with MS Plate. |

|---|---|

| Hydraulic Cylinder | Fabricated with seamless tube and hard chromium plated EN 8 rod. |

| Power pack | Fabricated with MS Plates. Fully assembled with directional control valves, pressure controls and all standard accessories. |

| Control Panel | Fully automatic panel for manual and automatic operations. |